Relationship Between Nozzle Breakage Waveform Ink Path Mechanisms

2025-12-31 点击次数:18

I. Core Principles: The Working Logic of Waveform Ink Path

A waveform is essentially a voltage timing signal that drives the piezoelectric ceramic (PZT) of the printhead.

It controls the state of the ink path through the waveform's tilt segment slope (rate of voltage change) and dwell time

(duration of stable voltage):

Ink Path Pressure Regulation: Voltage changes cause the PZT to expand and contract, altering the ink chamber volume.

When the voltage decreases, the chamber expands to draw in ink; when it increases, the chamber contracts to expel a

droplet. This process relies on the precise transmission of pressure waves.

Ink Motion Synchronization: The waveform pulses must match the pressure resonance of the ink within the chamber,

akin to timing a "push on a swing." Correct timing enhances droplet momentum, while incorrect timing induces impact.

II. Three Mechanisms by Which Waveform Ink Path Anomalies Cause Nozzle Breakage

Nozzle breakage (including nozzle clogging and fatigue fracture of needle-like structures) is directly triggered by ink

path pressure imbalance or mechanical shock. Mismatched waveform parameters are the core root cause:

Pulse Timing Mismatch: Pressure Resonance Conflict

Principle: The ink chamber can be viewed as a "damped resonator." The period of pressure wave propagation back

and forth within the chamber is determined by chamber length and ink sound speed. If the waveform pulse width is

too short/long, the pressure wave generated by a new pulse will cancel out or superimpose with the preceding wave:

Cancellation: Insufficient droplet ejection force leads to ink retention and dry clogging at the nozzle, causing

"pseudo-nozzle breakage" over the long term.

Superimposition: Pressure in the chamber surges abruptly, exceeding the mechanical tolerance limits of the PZT or

nozzle, leading to fatigue fracture of the needle-like structure.

Example: When using a universal waveform with high-viscosity ink, the resonance period extends due to reduced ink

sound speed. This pulse timing mismatch can increase the breakage rate by over 30%.

Uncontrolled Pressure Fluctuation: Mechanical Shock Overload

Voltage Amplitude Anomaly: The waveform's amplitude directly determines the PZT's deformation. An overly high

amplitude causes excessively violent chamber contraction, drastically increasing the ink's impact force on the nozzle

— similar to a "high-pressure water jet hitting glass," causing bending and fracture of the needle-like structure.

An overly low amplitude prevents complete ink ejection; residual ink mixes with impurities to form clogs, indirectly

leading to breakage.

Ink Supply Coordination Failure: The ejection rhythm controlled by the waveform must synchronize with the ink

supply pressure. If the supply pressure is unstable (e.g., low ink cartridge level), ink fails to replenish in time when

the waveform drives the PZT to contract. This creates negative pressure in the chamber, causing the nozzle to draw

in air. Subsequent pulses then generate a "water hammer effect" during pressure surge, impacting and breaking the

nozzle.

Multi-Nozzle Interference: Resonance Coupling Damage

Adjacent Nozzle Pulse Interference: Some printheads use a multi-nozzle shared chamber design. If the waveform pulse

timings of adjacent nozzles overlap, pressure waves couple between chambers. For instance, the three-pulse waveform

of a left nozzle overlapping with the single-pulse waveform of a right nozzle can cause abnormal pressure in

intermediate nozzles, leading to localized breakage.

Frequency Compatibility Failure: As printing frequency increases, pressure waves from prior pulses haven't attenuated

before new pulses trigger ejection, creating a "pressure accumulation effect." When the frequency approaches the

printhead's resonant frequency, the pressure peak can exceed twice the normal value, directly causing fracture of the

needle-like structure.

Waveform-Ink Mismatch: Chronic Clogging Induction

Lack of Moisturizing Function: High-quality waveforms incorporate a "pre-pulse" design—applying a micro-amplitude

pulse during non-ejection to induce slight ink flow inside the nozzle, preventing dry clogging. If the waveform lacks this

function or the pre-pulse amplitude is insufficient, volatile components in the ink evaporate, forming solid particles that

clog the nozzle, creating a "nozzle breakage" illusion. Forced printing further wears down the needle-like structure.

Compatibility Issues: The surface tension difference between mild solvent ink and aqueous ink is significant. If the tilt

segment slope of the waveform is not adjusted accordingly, it can cause "wetting-line retention" of ink at the nozzle,

leading to clogging-type breakage over long-term accumulation.

III. Typical Scenarios and Verification Methods

| |Breakage Type | Waveform/Ink Path Anomaly Characteristics | Detection & Verification Means |

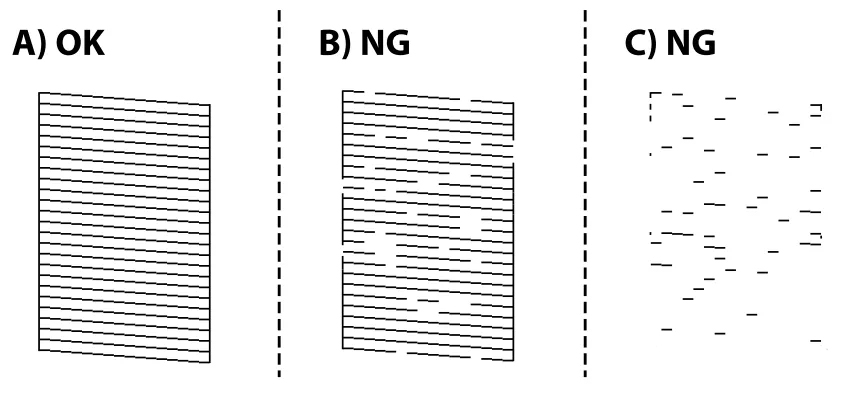

| |Clogging-Type Breakage | Waveform pulse trailing edge slope too gentle, droplet tailing | JetXpert observation shows

abnormal nozzle meniscus bulge |

| |Fatigue Fracture-Type | Waveform amplitude fluctuation >5%, obvious pressure wave superimposition | Oscilloscope

detects waveform distortion with peak glitches |

| |Impact Fracture-Type | Pulse width mismatch with ink sound speed adaptation >10% | Measure ink sound speed,

compare with waveform resonance period setting |

The waveform ink path is the core control center for the printhead's "pressure-motion-timing." The adaptability of

its parameters with the printhead structure, ink characteristics, and ink supply system directly determines the risk of

nozzle breakage. In essence, nozzle breakage is a synergistic failure of the waveform-controlled pressure signal with

the printhead's mechanical performance and the ink's physical properties—not a single component malfunction.